Guangxing

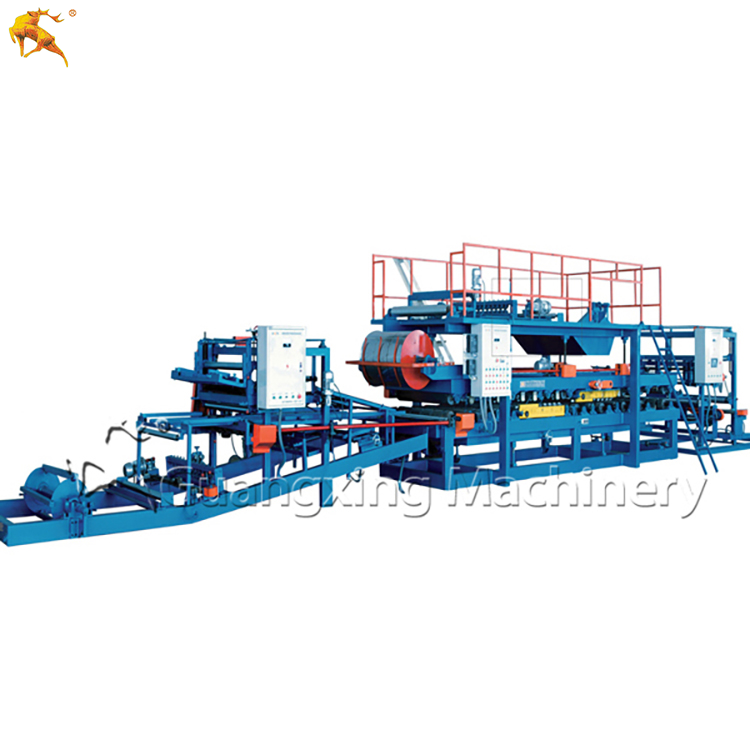

EPS Sandwich Panel

EPS Sandwich Panel

EPS Sandwich Panel

1) With reasonable structure, the machine is easy to operate with completed functions.

2) The plate is formed through such processes as feeding, profiling , dispensing, heating, trimming, gouging and cutting.

3) The machine adopts precise low-speed metering pump, frequency control (or stepless speed variation) with computer control and dose is accurate.

4) It can produce flat plate and corrugated sheet of many specifications and models, including the sandwich panel with thickness of 40-300mm and width of 950-1200mm, and corrugated high-intensive composite board with thickness of 40-300mm and width of 950-980mm.

5) This machine applies to color steel plate, aluminum plate, stainless steel plate and so on.

EPS Sandwich Panel can be used in a large color steel sandwich panel, central air conditioning, building wall material, cold storage, cold rooms, incubators, Chemical tanks, work plants, temporary worker-house, etc.

|

Item |

Specification |

|

Raw material |

Normally 0.2-0.6 aluminum or color steel |

|

Speed |

3-6m/min (Depend on the working temperature) |

|

Cutting type |

Trace flying saw cutting |

|

Drive |

Chain drive |

|

Electric control system |

PLC frequency conversion control |

|

Core material |

EPS board or rock wool |

|

Total power |

35kw |

|

Power supply |

380V/50HZ Or Customized |

|

Annual Output |

600 thousand square meters |

|

Product width |

950-1200 mm (Flat Plate) 950-980 mm (Corrugated Composite Board) |

|

Product thickness |

40-300mm |